Grenoble: a five-axis machining centre, unparalleled in France

Scientific culture, Innovation, Research

On March 14, 2022

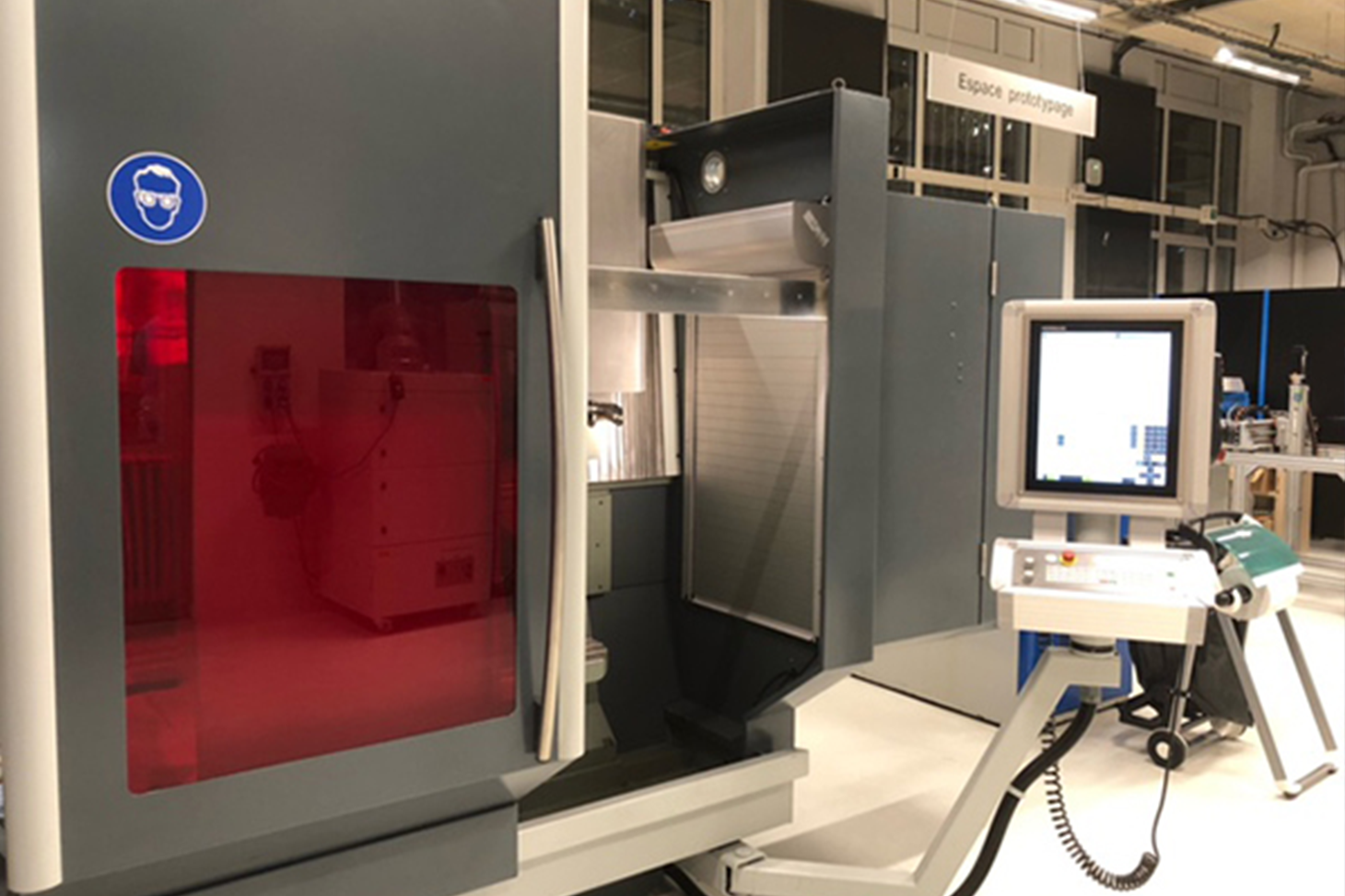

A new piece of equipment, the only of its kind in France, has just joined the GINOVA technological platform at the S.mart Grenoble Alps hub: a five-axis machining centre combining machining and manufacturing of metal additives.

More modern, easily manageable and versatile, the new five-axis machining tool recently added to the GINOVA platform at the S.mart Grenoble Alps hub represents a significant upgrade compared to the old three-axis machine. This tool, acquired second-hand and customised especially for GINOVA by the company Ratmo, makes it possible to manufacture metal parts with hundredth-of-a-millimetre accuracy, using three translation axes (the same as the old machine) plus two extra rotation axes.

And that is not all. It has also been fitted with a new tool: a wire fusion metal additive manufacturing head. “This additive manufacturing head is handled like a traditional tool, which makes it possible to program movement trajectories while depositing molten material,” explains Alain Di Donato, technical manager of the GINOVA platform at the S.mart Grenoble Alps hub. “This means that material can be added only where needed, with millimetre-level precision by melting metal wire, then finely machining it with 100 times more precision. This combination of technologies provides one-shot manufacturing capabilities that are higher-performing than the former equipment.” As well as saving considerable time, the ability to go from additive manufacturing to fine machining without changing machine makes it possible to produce parts with complex geometry quickly and with greater agility than with a sequential solution: additive manufacturing machine + machining tool.

And that is not all. It has also been fitted with a new tool: a wire fusion metal additive manufacturing head. “This additive manufacturing head is handled like a traditional tool, which makes it possible to program movement trajectories while depositing molten material,” explains Alain Di Donato, technical manager of the GINOVA platform at the S.mart Grenoble Alps hub. “This means that material can be added only where needed, with millimetre-level precision by melting metal wire, then finely machining it with 100 times more precision. This combination of technologies provides one-shot manufacturing capabilities that are higher-performing than the former equipment.” As well as saving considerable time, the ability to go from additive manufacturing to fine machining without changing machine makes it possible to produce parts with complex geometry quickly and with greater agility than with a sequential solution: additive manufacturing machine + machining tool.

Published on March 21, 2022

Updated on March 21, 2022

Updated on March 21, 2022